Submersible Dredging/Slurries/Solids

Global Pump Dragflow heavy duty submersible agitator pumps are designed for handling slurries with a high content of abrasive solids. The pumps have been extremely successful for clients operating in specialized sectors who face severe conditions and difficult applications including dredging in the marine and energy sectors as well as in mining for minerals and other materials. Handling slurries with up to 70% solids content and specific gravity up to 1.7, with a capacity of up to 5300 gpm at 275 feet of head.

Download cutsheet (.pdf)

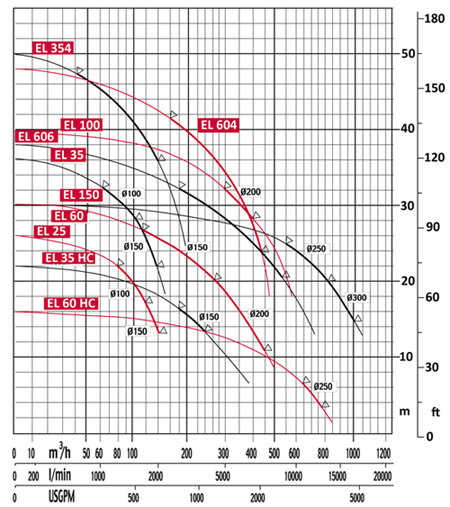

Electric Pumps (EL Series)

- Power: from 5 to 150 HP

- Capacity: from 150 to 4500 gpm (34 to 1022 m3/h)

- Head: from 15 to 275 ft (5 to 84 m)

- Discharge distance: up to 3300 feet (1000 m)

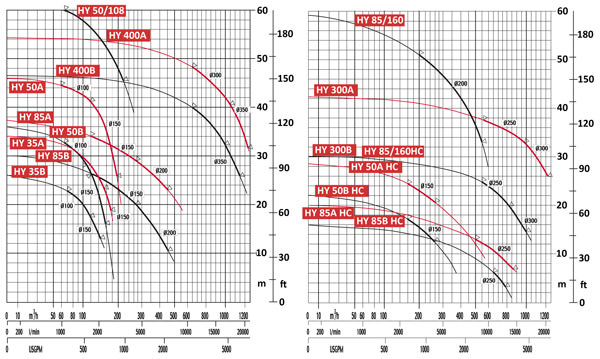

Hydraulic Pumps (HY Series)

- Power: from 24 to 400 Horse Power

- Capacity: from 165 to 5300 gpm (37 to 1204 m3/h)

- Head: from 15 to 275 ft (5 to 84 m)

- Discharge distance: up to 4300 ft (1300 m)

VARIED APPLICATIONS

Removal of silt build up at marinas, harbors, dock loading facilities, etc. / Waste sludge handling / Tank clean out / Waste collection ponds / Dredging deep deposits (up to 120 m deep) / Sands mining / Barge unloading / Waste collection pit / Ash sumps / Dredging waste ponds / Clean up sumps / Gold tailings reclamation / Settling and collection ponds / Underground slimes collection ponds / Conveyor tunnel sumps / Coal tailings relocation / Crusher sumps / Grinding area sumps / Flotation area sumps / / Truck wash sumps / Mill scale pits / Coke plant scale pit / Blast furnace slag pit / Water treatment sumps / Clean out caissons in construction / Transfer of bentonite slurry / Overburden removal / Reclaiming beaches / River, lake and canal clean out

- Electric motors are all Class H insulated and have a minimum 1.25 service factor.

- Pumps are equipped with a unique lip seal system to prevent material from penetrating the seal.

- High quality materials ensure long life of all components.

- Temperature sensor, embedded in the electric motor, and Moisture sensor, in the oil chamber, are available options to protect the pump in the most demanding application.

- Adjustable Hi-Chrome suction side Wear Plate maintains maximum performance for extended periods by a simple adjustment of the gap between the wear plate and the impeller.

- Replaceable wear parts: casings, impellers, wear plates all can be replaced independently.

- Lube Oil Inspection Ports: a wideangle port outside the pump ensures easy inspection of shaft seal oil levels as well as providing easy access for oil replacement.

- The excavating action is created by the Hi-Chrome agitator blades that lift settled sediments which then get sucked into the pump, creating a continuous flow of concentrated slurry.